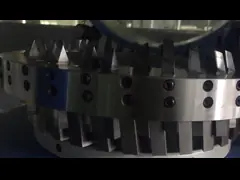

ODM Solid Carbide Cutter Semi finishing carbide CNC Lathe Cutting Tools

Add to Cart

Carbide Cutting Tools Made In China---110×15.24×15.24

What is the difference between turning and milling?

1. Different characteristics

Turning means that lathe processing is a part of mechanical

processing. Lathe machining mainly uses turning tools to turn the

rotating workpiece. Lathes are mainly used to process shafts,

discs, sleeves and other workpieces with revolving surfaces, and

are the most widely used type of machine tool in machinery

manufacturing and repair factories.

CNC lathes can process complex rotary shapes. Milling is to fix the

blank, and use a high-speed rotating milling cutter to run on the

blank to cut out the required shapes and features. Traditional

milling is mostly used to mill simple contour features such as

contours and slots.

2. Different functions

Turning is a method of cutting a workpiece on a lathe using the

rotation of the workpiece relative to the tool. The cutting energy

of turning is mainly provided by the workpiece rather than the tool

The milling and boring machining center can perform three-axis or

multi-axis milling and boring processing for machining, molds,

inspection tools, tire tools, thin-walled complex surfaces,

artificial prostheses, blades, etc. When selecting CNC milling

processing content, the advantages and key roles of CNC milling

machines should be fully utilized.

The dimensions of this image are for reference only