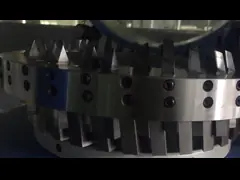

M2 Custom Gear Shaving Cutter Conventional Coated Normal Module

Add to Cart

M2 Material Normal Module Conventional Type Gear Shaving Cutter

Coated Tool Materials

Coating the tool is one of the important ways to improve the tool

performance. The emergence of coated tools has made a major

breakthrough in the cutting performance of tools. The coated tool

is coated with one or more layers of refractory compound with good

wear resistance on the tool body with good toughness, which

combines the tool matrix with the hard coating, thereby greatly

improving the performance of the tool. Coated tools can improve

machining efficiency, improve machining accuracy, extend tool life

and reduce machining costs.

About 80% of the cutting tools used in new CNC machine tools use

coated tools. Coated tools will be the most important tool

varieties in the field of CNC machining in the future.

(1) Types of coated tools

According to different coating methods, coated tools can be divided

into chemical vapor deposition (CVD) coated tools and physical

vapor deposition (PVD) coated tools. Coated cemented carbide tools

generally use chemical vapor deposition, and the deposition

temperature is around 1000 °C. Coated high-speed steel tools

generally use physical vapor deposition, and the deposition

temperature is around 500 °C;

According to the different substrate materials of coated tools,

coated tools can be divided into carbide-coated tools, high-speed

steel-coated tools, and coated tools on ceramics and superhard

materials (diamond and cubic boron nitride).

According to the nature of the coating material, coated tools can

be divided into two categories, namely "hard" coated tools and

"soft" coated tools. The main goal of "hard" coated tools is high

hardness and wear resistance. The main advantages are high hardness

and good wear resistance, typically TiC and TiN coatings. The goal

of "soft" coating tools is a low coefficient of friction, also

known as self-lubricating tools, which have friction with the

workpiece material. The coefficient is very low, only about 0.1,

which can reduce bonding, reduce friction, and reduce cutting force

and cutting temperature.

Nanoeoating tools have recently been developed. This coated tool

can use different combinations of various coating materials (such

as metal/metal, metal/ceramic, ceramic/ceramic, etc.) to meet

different functional and performance requirements. Reasonably

designed nano-coating can make the tool material have excellent

anti-friction, anti-wear and self-lubricating properties, which is

suitable for high-speed dry cutting.

(2) Characteristics of coated tools

① Good mechanical and cutting performance: The coated tool combines

the excellent properties of the base material and the coating

material, which not only maintains the good toughness and high

strength of the base, but also has the high hardness, high wear

resistance and low strength of the coating. friction coefficient.

Therefore, the cutting speed of the coated tool can be more than 2

times higher than that of the uncoated tool, and a higher feed rate

is allowed. The life of the coated tool is also improved.

② Strong versatility: Coated tools have a wide range of

versatility, and the processing range is significantly expanded.

One coated tool can be used instead of several non-coated tools.

③ Coating thickness: With the increase of coating thickness, the

tool life will also increase, but when the coating thickness

reaches saturation, the tool life will no longer increase

significantly. When the coating is too thick, it is easy to cause

peeling; when the coating is too thin, the wear resistance is poor.

④ Regrindability: The regrindability of the coated blade is poor,

the coating equipment is complex, the process requirements are

high, and the coating time is long.

⑤ Coating material: Tools with different coating materials have

different cutting performance. For example, when cutting at low

speed, TiC coating is dominant; when cutting at high speed, TiN is

more suitable.

(3) Application of coated tools

Coated tools have great potential in the field of CNC machining,

and will be the most important tool variety in the field of CNC

machining in the future. Coating technology has been applied to end

mills, reamers, drills, compound hole machining tools, gear hobs,

gear shapers, shaving cutters, forming broaches and various

machine-clamped indexable inserts to meet the needs of high-speed

cutting machining. The needs of materials such as steel and cast

iron, heat-resistant alloys and non-ferrous metals.