Add to Cart

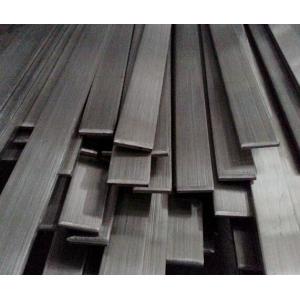

Hot Rolled Flat Steel Bars Of Q195, Q215, Q235, Q345, GB704 Mild Steel Product

| Product name | Hot Rolled Flat Bar of Q195, Q215, Q235, Q345, GB704 Mild Steel Product | ||

| Standard | ASTM, AISI, EN, DIN, JIS, GB | ||

| Grate | A36, S235JR, S355JR,St37-2, SS400, Q235, Q195,Q345 | ||

| Technique | hot rolled, slitted, round edge | ||

| Size | Width | Thickness | Length |

| 10-200mm | 1.5-30mm | 6m, 9m, 12m or customized | |

| OEM | yes | ||

| Tolerance | As the standard or your requirement | ||

| Application | Construction/Shipbuilding/Machinery manufacturing/Steel structure | ||

| Features | 1. High quality | ||

| 2.High dimensional accuracy | |||

| 3. High utilization rate of material | |||

| 4. Saving cost price | |||

| Packing Details | 1. Iron sheet in both ends | ||

| 2.All wrapped packing with plastic woven bag | |||

| 3.Loose package | |||

| 4.As the requirement of customer. | |||

What are the main differences between hot rolled flat and cold

drawn flat?

The key difference between hot rolled flat steel and cold drawn

flat steel is the processing technology. With the development of

cold drawn flat steel in hot rolling, its processing accuracy and

surface finish are improved gradually.

The working principle of the flat finishing machine is to

pre-calibrate and finally calibrate the thickness direction of the

cold flat steel wool with two groups of staggered leveling wheels.

The width direction is extruded by a pair of relative arrangement

of finishing wheels, so that the width is compressed to reach the

desired parameters, and the compression amount is adjustable. Use 5

staggered alignment wheels to straighten its width. The system is

mainly composed of control box, finishing roller, pre-leveling

unit, finishing unit and straightening unit.

Its production process can be summarized as: pre-leveling →

finishing → straightening → after leveling. Flat steel/A/B 12-300mm

wide, 4-60mm thick, rectangular section with slightly pure edge

steel. Flat steel can be finished steel, can also be used as a

blank for welding pipe and thin slab for rolling sheet. Main uses:

flat steel as a finished material can be used for hoop iron, tools

and mechanical parts, as building frame structure, escalator. Flat

steel is divided into two kinds according to its shape: flat spring

flat steel and single surface double groove spring flat steel. Hot

rolled spring flat steel is mainly used in manufacturing

automobile, tractor, railway transport and other mechanical leaf

springs.

Square steel - square section of steel, hot rolled and cold rolled;

Hot rolled square steel side length 5-250mm; Cold-drawn square

steel side length 3-100mm.

Round steel - round section of steel, hot rolled, forged and cold

drawn three, hot rolled round steel 5-250mm in diameter, which

5-9mm commonly used to do the raw material of the drawing wire,

called wire; As a result of the plate supply is also called hot

rolled wire rod. Forged round steel straight is thicker, used as

shaft blank. Cold-drawn round steel diameter 3-100mm, high

dimensional accuracy.

Angle - equilateral Angle and unequal Angle two kinds. Angle steel

specifications are indicated by the dimensions of side length and

side thickness. Angle bars are usually produced in sizes 2-20, i.e.

centimeters of side length. For example, No. 5 equilateral Angle

steel refers to the Angle steel with a side length of 5cm (50mm).

The same Angle steel often has 2-7 different edge thicknesses.