Add to Cart

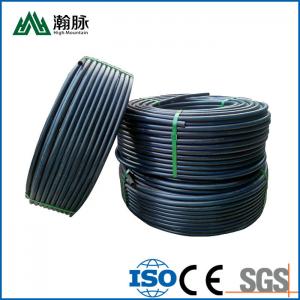

New Product HDPE Water Supply Pipe 25 32 PE Pipe 4 Inch High

Quality Density Polyethylene Pipes For Drinking Water

----------------------------------------

Basic Info.

HDPE water supply pipe appearance: The inner and outer surfaces of

the pipe should be clean and smooth, and no bubbles, obvious

scratches, dents, impurities, uneven color and other defects are

allowed. The end of the pipe should be cut flat and perpendicular

to the pipe axis.

HDPE water supply pipe color: the color of municipal drinking water

pipe is blue or black, and the black pipe should have a co-extruded

blue color bar. There are at least three color bars along the

longitudinal direction of the pipe. Water pipes for other purposes

can be blue and black. Laying pipes exposed to the sun (such as

above-ground pipes) must be black.

HDPE water supply pipe length: The straight pipe length is

generally 6m, 9m, 10m, 12m, and it can also be negotiated between

the supplier and the buyer. The limit deviation of the length is

+0.4% and -0.2% of the length. The diameter of the coil frame

should not be less than 18 times the outer diameter of the pipe,

and the expanded length of the coil should be negotiated between

the supplier and the buyer.

| Outer Diameter DN (mm) | SDR 9 PN20 | SDR 11 PN16 | SDR 13.6 PN12.5 | SDR 17 PN10 | SDR21 PN8 | SDR26 PN6 | Packing Loaded into 40GP/Piece 6m or 12m per Piece |

| Wall Thick Ness(mm) | Wall Thick Ness(mm) | Wall Thick Ness(mm) | Wall Thick Ness(mm) | Wall Thick Ness(mm) | Wall Thick Ness(mm) | ||

| 75 | 8.4 | 6.8 | 5.6 | 4.5 | 1085 | ||

| 90 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | 754 | |

| 110 | 12.3 | 10 | 8.1 | 6.6 | 5.3 | 4.2 | 504 |

| 125 | 14 | 11.4 | 9.2 | 7.4 | 6 | 4.8 | 378 |

| 140 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 | 304 |

| 160 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 | 224 |

| 180 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 | 182 |

| 200 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 | 143 |

| 225 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 | 110 |

| 250 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 | 90 |

| 280 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 | 72 |

| 315 | 35.2 | 28.6 | 23.2 | 18.7 | 15 | 12.1 | 56 |

| 355 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 | 42 |

| 400 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 | 30 |

| 450 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 | 25 |

| 500 | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 | 20 |

| 560 | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 | 16 |

| 630 | 70.3 | 57.2 | 46.3 | 37.4 | 30 | 24.1 | 12 |

| 710 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 | 9 | |

| 800 | 72.7 | 58.8 | 47.4 | 38.1 | 30.6 | 6 | |

| 900 | 81.8 | 66.2 | 53.3 | 42.9 | 34.4 | 6 | |

| 1000 | 90.2 | 72.5 | 59.3 | 47.7 | 38.2 | 4 | |

| 1200 | 88.2 | 67.9 | 57.2 | 45.9 | |||

| 1400 | 102.9 | 82.4 | 66.7 | 53.5 | |||

| 1500 | 110.2 | 88.2 | 71.4 | 57.6 | |||

| 1600 | 117.6 | 94.1 | 76.2 | 61.2 |

Advantage

1. High strength, excellent resistance to environmental stress cracking, and good creep resistance;

2. Good toughness, flexibility, strong adaptability to uneven foundation and dislocation, and can withstand harsh environments such as earthquakes and typhoons;

3. It has good weather resistance (including UV resistance) and long-term thermal stability;

4. Corrosion resistance, no need for anti-corrosion treatment, long service life;

5. The inner wall is smooth, the water flow resistance is small, the circulation capacity is large, and the construction cost is saved;

6. Good wear resistance and anti-wear;

7. Good low-temperature impact resistance, which can be safely affected in the temperature range of -20~40℃;

Details

Application

1. Urban tap water pipe network system.

2. Urban and rural drinking water pipelines.

3. Material and liquid transportation pipelines in chemical, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, papermaking, metallurgical and other industries.

4. Agricultural irrigation pipes.

5. Protective sleeves for post and telecommunications lines and power wires.

6. Mine mortar conveying pipeline.

7. Protective sleeves for post and telecommunications lines and power wires.

Certificate

Company Profile

High Mountain Pipe Industry is a specialized enterprise that

produces anticorrosive plastics (pp, frpp, pe, hdpe, pvdf, pph,

upvc, cpvc, abs) pipes, fittings, plates, and valves. The company

has various assets of more than 61.8 million yuan, 10 pipe

production lines, 2 pipe fittings production lines, and 1 sheet

production line. It has a production capacity of more than 8,000

tons of various anti-corrosion plastic products. The pipe

production caliber can reach 1200mm, the plate production width can

reach 2000mm, and the length is unlimited. In 2006, the company

passed ISO9001-2000 quality management system certification,

ISO14001 environmental system certification, OHSA18001 occupational

health and safety system certification, CMMI certification, and

IEC27001 information security system certification.

FAQ

Q: Why choose us?

A: We are a professional manufacturer with competitive price,

excellent quality and fast delivery time.

Q: How to get free samples?

A: Send your address, telephone number, zip code and express

account number to our mailbox, and tell us which model of samples

you need. Our sales team will contact you within 24 hours.

Q: What is your minimum order quantity?

A: Accessories: one box or one bag.

Pipeline: 200~5000 meters/size, depending on different sizes.