Add to Cart

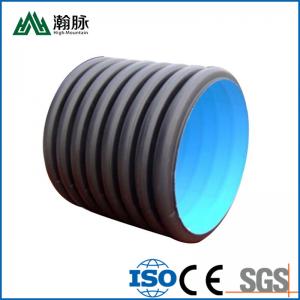

High Quality And Low Price HDPE Double Wall Corrugated Pipe Plastic Water Drainage Pipe

----------------------------------------

Basic Info.

HDPE double-wall corrugated pipe is a flexible pipe. Our company can provide users with DN200mm-DN1200mm, standard lengths of 6m, 12m, various specifications of reinforced plastic pipes and related supporting pipe fittings. The above products are strictly in accordance with GB/T19472.1-2004. Standard implementation. The raw material used is a PE100 high-density polyethylene pipe material. Due to its reasonable structure design and innovative production technology, the product has a smooth inner surface and a hollow outer profile corrugated rib, ensuring the mechanical strength of the pipe. Has been widely used in engineering

| Size | PN2.0MPa | PN1.6MPa | PN1.25MPa | PN1.0MPa | PN0.8MPa | PN0.6MPa | |

| SDR 9 | SDR 11 | SDR 13.6 | SDR 17 | SDR 21 | SDR 26 | ||

| OD(inch) | OD(mm) | thickness | thickness | thickness | thickness | thickness | thickness |

| 1/2 | 20 | 2.3 | 2.3 | ||||

| 3/4 | 25 | 3 | 2.3 | 2.3 | |||

| 1 | 32 | 3.6 | 3 | 2.4 | |||

| 1 1/4 | 40 | 4.5 | 3.7 | 3 | 2.4 | ||

| 1 1/2 | 50 | 5.6 | 4.6 | 3.7 | 3 | ||

| 2 | 63 | 7.1 | 5.8 | 4.7 | 3.8 | ||

| 2.5 | 75 | 8.4 | 6.8 | 5.6 | 4.5 | ||

| 3 | 90 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | |

| 4 | 110 | 12.3 | 10 | 8.1 | 6.6 | 5.3 | 4.2 |

| 5 | 125 | 14 | 11.4 | 9.2 | 7.4 | 6 | 4.8 |

| 5 | 140 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 |

| 6 | 160 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 |

| 7 | 180 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 |

| 8 | 200 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 |

| 8 | 225 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 |

| 10 | 250 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 |

| 11 | 280 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 |

| 12 | 315 | 35.2 | 28.6 | 23.2 | 18.7 | 15 | 12.1 |

| 14 | 355 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 |

| 16 | 400 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 |

| 18 | 450 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 |

| 20 | 500 | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 |

| 22 | 560 | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 |

| 24 | 630 | 70.3 | 57.2 | 46.3 | 37.4 | 30 | 24.1 |

| 28 | 710 | 79.3 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 |

| 32 | 800 | 89.3 | 72.6 | 58.8 | 47.4 | 38.1 | 30.6 |

| 36 | 900 | 81.8 | 66.2 | 53.3 | 42.9 | 34.4 | |

| 40 | 1000 | 90.2 | 72.5 | 59.3 | 47.7 | 38.2 | |

| 48 | 1200 | 88.2 | 67.9 | 57.2 | 45.9 | ||

| 55 | 1400 | 102.9 | 82.4 | 66.7 | 53.5 | ||

| 60 | 1500 | 110.2 | 88.2 | 71.4 | 57.6 | ||

| 65 | 1600 | 117.6 | 94.1 | 76.2 | 61.2 |

Advantage

1. Reliable connection: The polyethylene piping systems are

connected by electrothermal fusion, and the strength of the joint

is higher than that of the pipe body.

2. Good impact resistance at low temperature: The low temperature

embrittlement temperature of polyethylene is extremely low, and it

can be used safely in the temperature range of -60-60 °C. During

construction in winter, due to the good impact resistance of the

material, the pipe will not be brittle.

3. Good resistance to stress cracking: HDPE has low notch

sensitivity, high shear strength and excellent scratch resistance,

and its resistance to environmental stress cracking is also very

outstanding.

4. Good chemical corrosion resistance: HDPE pipes are resistant to

corrosion by a variety of chemical media, and the chemicals present

in the soil will not cause any degradation to the pipes.

Polyethylene is an electrical insulator, so it does not rot, rust

or electrochemically corrode; it also does not promote algal,

bacterial or fungal growth.

5. Anti-aging and long service life: Polyethylene pipes containing

2-2.5% evenly distributed carbon black can be stored or used

outdoors for 50 years without being damaged by ultraviolet

radiation.

Details

Application

1.Replacement of cement pipes, cast iron pipes and steel pipes: For

the replacement of old pipes with cement pipes, cast iron pipes,

etc. originally laid in the city, PE pipes can be directly inserted

into the old pipes for replacement without extensive excavation,

and the project cost is low , The construction time is short,

especially suitable for the pipeline re-selection in the old city.

2. Landscaping pipe network: landscaping requires a large number of

water pipelines, and PE pipes have low cost and are worthy of

vigorous promotion.

3. Municipal trenchless engineering: At present, with the

development of the city, trenchless technology is widely used in

various constructions, and the pipe jacking (drag pipe, traction

pipe) commonly used in trenchless factories is currently more

popular. PE pipe, because of its toughness and price advantage,

will have greater development in the trenchless field.

4. Sewage treatment: At present, many sewage treatment plants use

PE pipes in addition to cement pipes and HDPE double-wall

corrugated pipes. In construction such as turning and crossing, its

convenience is even more prominent.

5. Electric power threading: Due to the superior resistance and

insulation properties of PE pipes, as well as its own good

compressive strength and tensile strength, it is often used in many

power threading constructions.

Certificate

Company Profile

High Mountain Pipe is a high-tech enterprise specializing in the production, research and development, sales and installation of new green and environmentally-friendly polyethylene pipes. The company has several intelligent numerical control production lines, which mainly produce and sell: 1. High-density polyethylene (HDPE) water supply pipe series products, including PE water supply pipes and fittings. Steel mesh skeleton PE composite pipes, pipe fittings, etc.; 2. High-density polyethylene (HDPE) drainage and sewage pipe series products, including double-wall corrugated pipes, trenchless sewage traction pipes, hollow wall winding pipes, and inner rib reinforced PE spiral corrugations Pipes, steel belt reinforced PE spiral corrugated pipes, reinforced winding corrugated pipes, etc.; 3. High-density polyethylene (HDPE)/MPP power, cable, and communication sheathing series products, including PE power, cable, and communication sheathing, MPP electric power, cables, communication jacket pipes, etc.; 4. HDPE various mine pipes.

FAQ

Q: Is it possible to use the label or packaging I specified?

A: Yes. If necessary, we would like to use labels or packaging

according to your requirements.

Q: What are your payment terms?

A: Accept the T/T and L/C terms.

Q: What certificates do you have for this product?

A: ISO, CE, SGS, etc.