Add to Cart

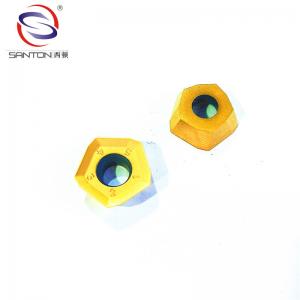

K40 Grade For High Manganese Steel And Stainless Steel High Feed Milling Inserts

Grade Information:

Santon Grade | Density(g/cm³) | TRS(n/mm²) | HRA | Performance & Applications | ISO Code |

| ST2090 | 14.2 | 2800 | 89.5 | Good toughness, excellent high resistance to thermal crack and plastic deformation, suitable for roughing of alloy structure steel, alloy steel, high manganese steel as well as stainless steel, an ideal material for rotor machining. | K40 |

Product description:

Relieving cutter

Behind it with shovel cutting (or shovel grinding) method processing Archimedes spiral tooth back, milling cutter with blunt only after heavy grinding front, can maintain the original tooth shape unchanged, used for manufacturing gear milling cutter and other forms of milling cutter

Certifications:

Company Information:

Santon Specializing in the production, research and development and sales of various coating NC turning, cutting, milling blades, grooving blades, cermet blades, end milling cutters, carbide NC blades and bars, and accept non-standard products customized to the drawings and samples, to provide perfect tool solutions for the machining and manufacturing industry.

we can provide not only all kinds of high quality standard cemented carbide products such as machine-clamped inserts,brazing inserts and high accuracy coated inserts for clients who are engaged in machining of ferrous metals ,non-ferrous metals

and non-metals ; but also various non-standard cutting tools and hard wearing parts according to customers' requirement . We can produce not only extensive used cemented carbide materials like P type,M type and k type,but also new types to satisfy users special needs.

FAQ:

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of

producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips,

geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit

and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for

new molds, the lead time may need 10days more to open molds. If you

need the goods urgently, we could try to push for and shorten the

delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be

paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re

not completely satisfied with our products ,we’ll replace them or

refund the fee

Q. Where is your market?

A. Our products are popular in Germany, America, Mexico, India,

Russia, Indonesia, Malaysia, Bangladesh, South Africa,etc.