Add to Cart

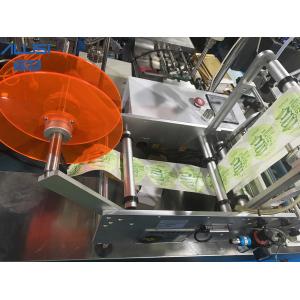

The Semi-Automatic Labeling Machine for Round Bottle is a cutting-edge beverage labeling solution designed to streamline and enhance the labeling process for round bottles. With its innovative features and user-friendly design, this bottle labeler ensures precise and efficient application of labels to various-sized round bottles used in the beverage industry.

Equipped with advanced technology, the machine offers semi-automatic operation, striking a perfect balance between manual control and automated accuracy. Its versatile labeling capability accommodates a wide range of bottle diameters and label sizes, maximizing flexibility and adaptability for different beverage products.

This labeling machine boasts quick setup and easy adjustments, reducing downtime and increasing productivity. The user-friendly interface allows operators to control labeling parameters effortlessly. Furthermore, its sturdy construction guarantees durability and long-lasting performance, making it a reliable addition to any production line.

Item NO.:APM

Lead Time:15 DAYS

Product Orgin:China

Shipping Port:Guangzhou

Payment:EXW, FOB, CIF, DDP, DDU etc.

Price:$1800/Set

MOQ1

Product Detail

Product Description:

1. Brief Induction of Automatic body cream, BB cream tube labeling machine

2. Note:The machine can be operated independently, and equipped with independent production line.

3. Product shaped:Soft Tubes (Equipped with special equipment to deal with 1 ml of the special small round product labeling.

4. Warning function:Warning when the ribbon is finished or broken, when there is a lack of label, products and other operation specifications

Feature

Semi-automatic operation: Combining manual control with automation, this machine strikes a balance between user intervention and precise label application.

Versatile bottle compatibility: The labeling machine can handle a wide range of bottle diameters and sizes, making it suitable for various round bottle types commonly found in the beverage industry.

Quick setup and adjustments: Easy-to-use controls and intuitive interface facilitate rapid setup and label size adjustments, reducing downtime and enhancing overall productivity.

Accurate labeling mechanism: The machine's advanced technology ensures precise and consistent label placement, maintaining a professional appearance for each labeled bottle.

Robust construction: Built with durable materials, the labeling machine is designed to withstand continuous use in demanding production environments, ensuring long-lasting performance.

Size Information:

No | Item | Description |

1 | Scope of applicable labels | width of 10-350mm, length of 10-150mm |

2 | Diameter of applicate bottle neck | external diameter of 20-80(mm), height of 30~200(mm) |

3 | Max roll inside diameter | 76mm |

4 | Production capacity | 1200~2400 bottles/hour |

5 | Total power | 100W |

Factory:

Our Service

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.