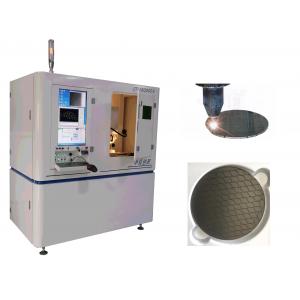

Product Details

Fiber Metal Laser Cutting Machine With Comptitive Price And

Maintance Free

ZT-JGQG6S is a new model of laser cutting machine. The

self-developed laser source makes better cutting performance,

completely replaced the traditional YAG cutting machine. Higher

cutting speed and thinner cutting kerf (2.0mm thickness PCD, the

cutting kerf is 0.06-0.08mm), smooth cutting surface, running

steady and maintenance-free. Suitable for cutting PCD/ PCBN/ CVD/

Sapphire/ PDC/ Cemented Carbide/Ceramics and other precious and

ultra-hard materials. Especially, it has incomparable advantages in

cutting low content PCBN.

Technical Parameters:

Power supply requirements | 380V50Hz, Five-core four-square power cord |

Working environment | Room temperature 20~40℃, humidity ≦60%, away from oil source |

Cooling Mode of Machine | Adopt dual temperature cooling system , laser cutting head cooled by room temperature water. Laser cooled

by 22℃cooling circulating water, and for manufacturing workpiece

cooled by purify oil-free compressed air. |

Laser Source | Fiber laser |

Duty Ratio | 1~100% |

Frequency | 1-2000 Hz |

Power percentage | 1%~100% |

Four Axis stroke | 300*300*50mm A-Axis 0±30° |

Maximun power output | 3000W |

Positioning accuracy | ≦± 0.005mm |

Repeat positioning accuracy | ≦± 0.005mm |

Daily maintenance and maintenance

1. Check the operation of the laser carefully before turn on daily,

check the equipment button indicator lamp, stop the ammonium button

key switch is not normal.

2. check the circulating water level of water cooler water tank, if

not added in time.

3. Check protective lens for damage before daily cutting.

4. Clean up the dust and debris inside the worktable after each

shift is completed.

5. After one year of using , the machine tool and worktable should

be adjusted regularly to ensure the cutting accuracy of the machine

tool.

If the equipment is not in use for a long time, please apply butter

to the moving parts and rust-prone parts of the machine tool to

prevent rust.

Company Profile

Originally founded by graduates from Tshinghua university, and we

was belong to Tshinghua universtity as a R&D . At 2003, CHN-TOP

become a independent company which focus on diamond tools(PCD,

PCBN,MD,ND,CVD) industries, produce high precision process

equipments.(PCD PCBN tools grinders, vacuum brazing machines, laser

cutting machines, chip breaker machines);We offer pre-machining

services(PCD/PCBN laser cutting, tools brazing, chip breaker

engraving, lapping and polishing,etc.), and distribute world famous

PCD and PCBN blanks;Also supply professional consultation and

advanced technical services, we are your only one stop shop in the

field of ultra-hard materials processing with good reputation in

global market. Our business scope is :

- CNC and manual grinders for PCD/PCBN milling, reaming, turning and

drilling tools ,etc.

- High precision laser cutting machine for PCD/PCBN/Ceramic and some

other valuable materials

- Special laser engraving machines for chip breaker and positioned

hole

- Automatic vacuum brazing machine and paste, widely used in

PCD/PCBN/CVD/Cardbide, etc.

- Offer diamond cutting tools' pre-machining: laser cutting, carbide

notching, brazing, chip breaker

- Ultra-hard material machinining: lampping, grinding and polishing,

etc.

- Provide high quality PCD/PCBN blanks and distribute world famous

brand materials.